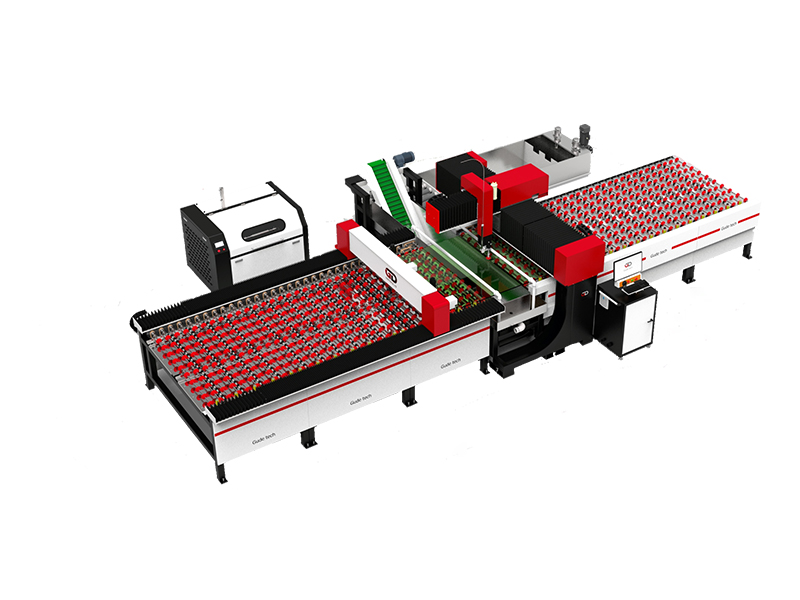

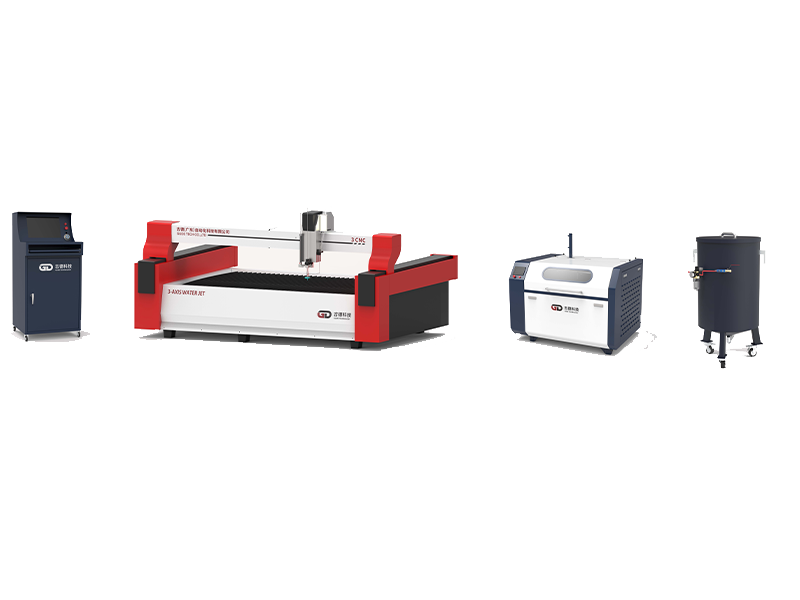

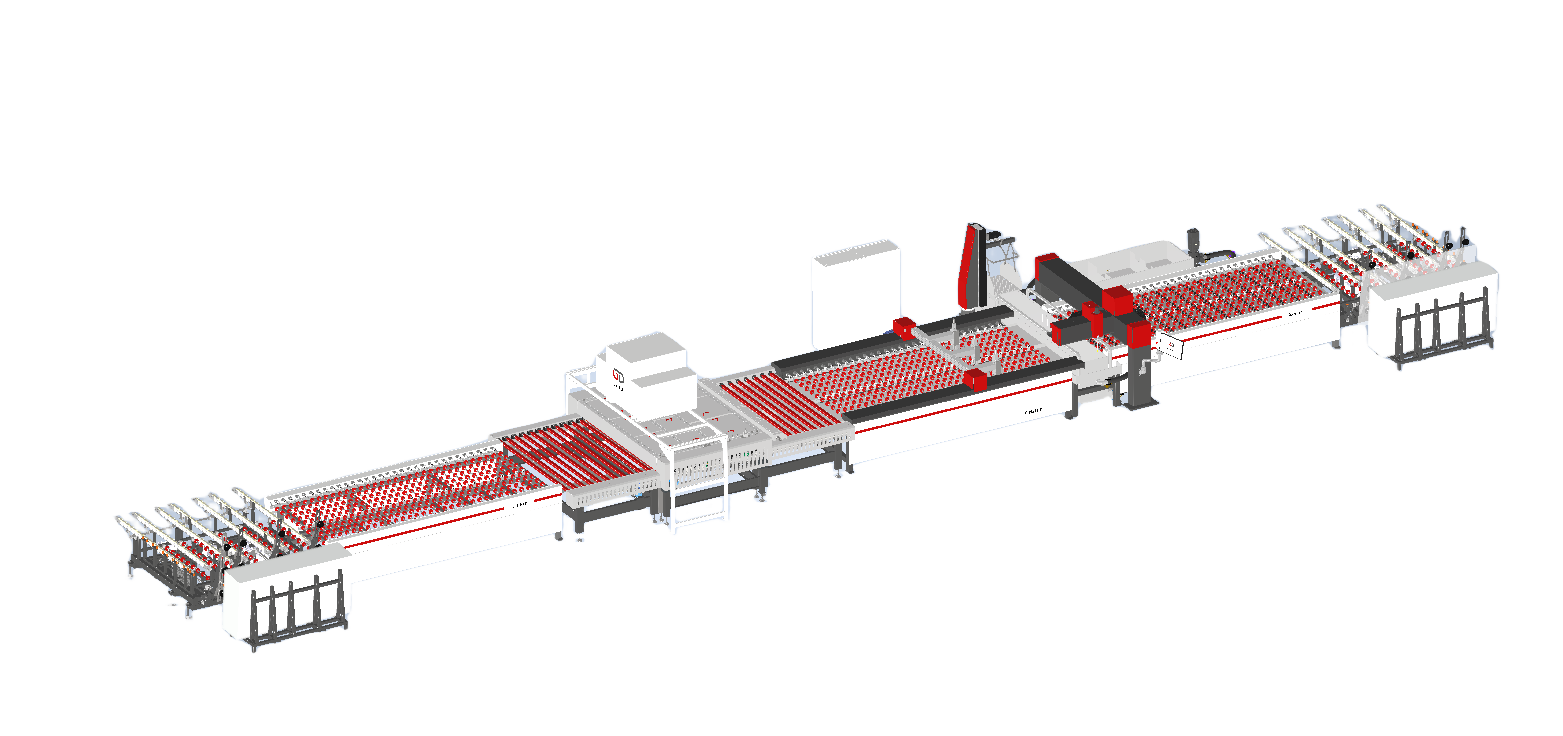

Modular gantry waterjet cutting machine

It has strong cutting capacity, stable performance, can work continuously for a long time, and is suitable for mass production.

Scope of application: The main cutting fields include glass, slate, ceramics, marble, composite materials, granite, aluminum, copper, steel, etc.

- Description

- Parameters

- Features

Modular gantry waterjet cutting machine

Modular gantry waterjet cutting machine has large module structure, convenient transportation. What’s more, it has high-precision ball screw, guide rail precision transmission, ball screw fast running bracket protection system, ESA PC, 19-inch true color touch screen control system and AC servo motor : automatic centralized lubrication system. The size of the machine tool can be customized according to customer needs.

- Model: DWJ3060

- Working desk size:

X axis: 3100mm; Y axis: 6100mm - Cutting stroke:

X axis: 3000mm

Y axis: 6000mm

Z axis: 300mm - Drive mode: AC servo

- Repeat positioning accuracy: ±0.025mm

- Maximum running speed: 20m/min

- Control system: ESA

- Cutting accuracy: ±0.15mm

- Power supply: 220V/380V/415VAC, 3P, 50Hz/60Hz

Solid and reliable bed design

Cantilever balance design, small footprint, easy to use;

Well-designed full casting structure, strong and stable, with higher strength;

The main vitality parts are selected from domestic brands, and the work is reliable.

Local details that lead the industry

Centralized automatic lubrication design, humanized design, automatic equipment maintenance;

Strong and durable brand drag chain, flexible movement, high-quality sensors;

Provide reliable soft limit for machine tools, safe and secure.

Well-crafted new solutions

The guide rail of the machine tool adopts labyrinth waterproof and sand-proof, plus soft curtain, double professional protection;

The machine tool with a stroke of more than 3m adopts a rotating nut structure for transmission, and the long-distance transmission is more reliable;

The use of high-quality ball screws and guide rails of international brands ensures the high precision of parts processing, balanced transmission and durability.

Enquiry Form ( we will get back you as soon as possible )

Maybe you like also

Any text can put here...