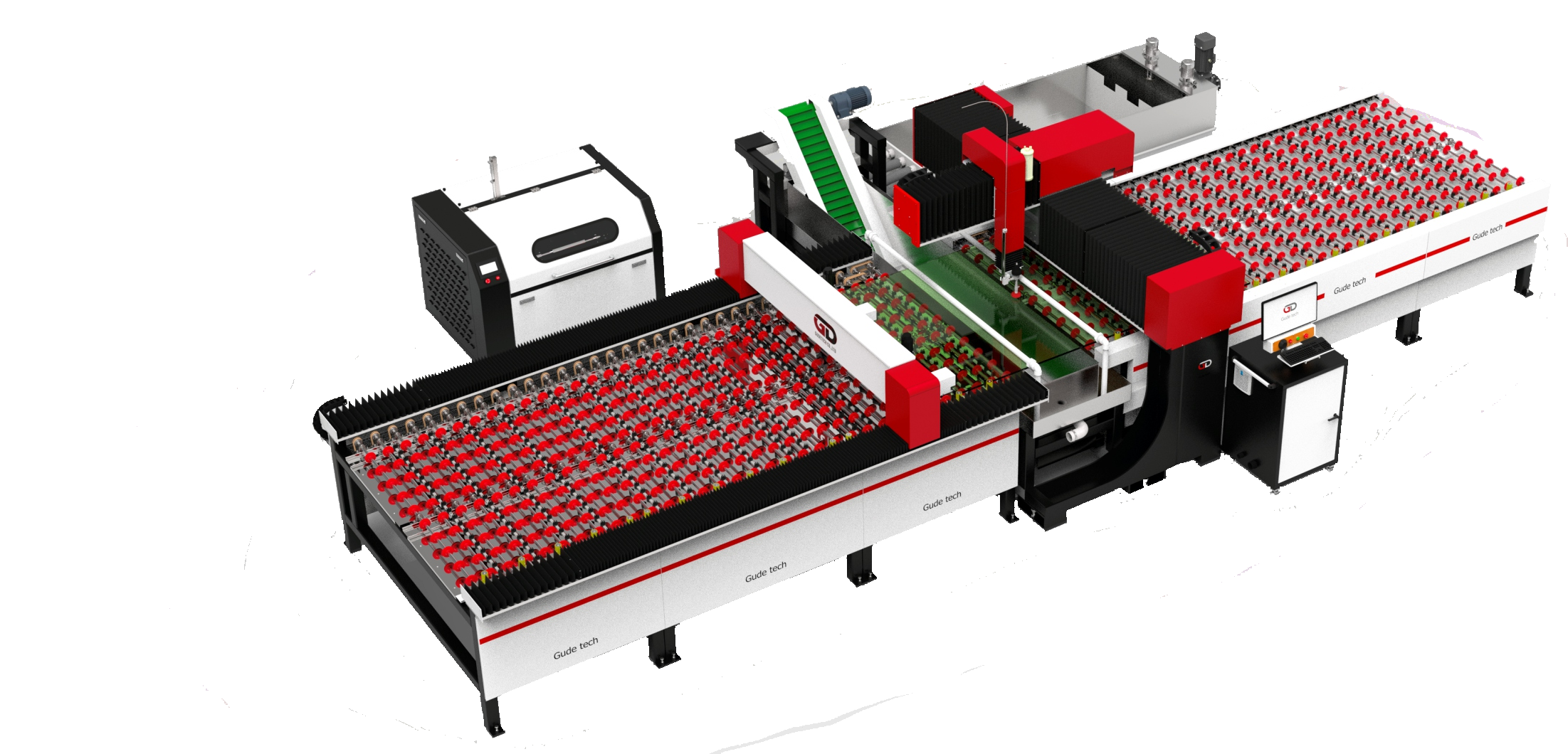

The water jet cutter of our company adopts the most advanced design concept and structural design at present, and is equipped with imported high-quality supercharger and automatic variable oil pump. It has strong cutting capacity, stable performance, can work continuously for a long time, and is suitable for

mass production.

The main cutting fields include glass, slate, ceramics, marble, composite materials, granite, aluminum, copper, steel, etc.

Scope of applications

Gudetech waterjets cut virtually any material. Gudetech cuts Glass crafts, Stainless steel plate, High hardness cast stone and any materials.

Glass crafts

Stainless steel plate

High hardness cast stone

Composite plastic sample

Ceramic

Aluminum parts

High tech materials

Any materials

Features of our cutting machines

The water jet cutter of our company adopts the most advanced design concept and structural design at

present, and is equipped with imported high-quality supercharger and automatic variable oil pump.

Who is Gudetech?

Gudetech, Your Trustable Waterjet Cutting Machinery manufacturer.

Gudetech is a professional manufacturer of water jet cutting machines. After repeatedresearch, practice and continuous innovation, we have successfully developed gantrythree-axis water jet cutting machine, AC five-axis water jet cutting machine, cantileverwater jet cutting machine and other related water jet cutting machines. Not only that,we can also customize water jet cutting machines for users to meet their needs.

In order to continuously innovate and improve the quality and performance of themachine, we continue to invest in technical talents, and spend more than 12% of ourannual turnover on research and development, and have obtained a number ofpatent certificates.

Our brand is well-known in various countries.”Professional, dedicated, responsible,and timely response” is the consistent evaluation of our customers. Our equipment isexported to the United States, Germany, the Middle East, South Korea, Canada,Singapore, Vietnam, India, Russia, Turkey, lran, Saudi Arabia, South Africa and othercountries.

We are looking forward to working closely with your company.

Take care of every detail of our machine

the oil tank, solved the serious accuracy attenuation problem of

water jet cutting machine in the past.

synchronous pulley belt connection. Within a millimeter, precision must reach.

operation.

Actively identify CAD electronic drawings, intelligently and automatically generate tool diameter adjustment parameters, reduce manual coding and repeated operations, simple operation, and

increase production capacity.

Have Questions?

WHY CHOOSE US

CONTACT US

Any text can put here...